Learning Objective- You will learn about safety equipment, safeguards, and safety rules in the jewelry classroom and apply your knowledge to the General Safety Quiz on Friday.

Language Objective- Students with listen and take notes on Safety in the jewelry classroom, creating a list to help them organize the topics of safety and studio areas of concern.

Agenda-

- Write down the following SAFETY Procedures:

- Make a list for each of the following topics:

- Pickle

- Buffing polishing wheels

- Torches

- General

- Test on Thursday!!!

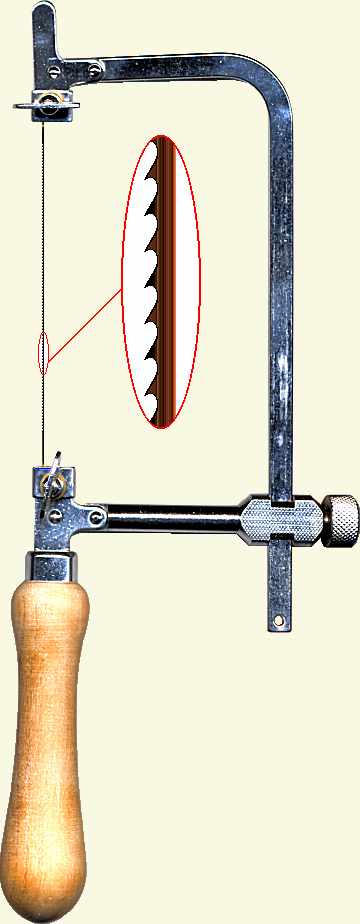

- Tips for Filing

- Put pressure on your metal on the downward or forward stroke of the file

- Think about the shape you're filing and the flat or curved surface of the file, (curved side goes on an inside curve of the design, flat file would be used on an outside curve).

- To get a smooth straight line use a long stroke to file along the edge as far as possible.

- Overlap your file strokes when moving to a new area of the piece.

- If a small section is extra bumpy and you want it to be smooth, work on the one spot to make it more even and then continue to file the whole piece.

- Filing Demonstration

- Work time

Homework-

Study for your Safety test on Thursday!!!